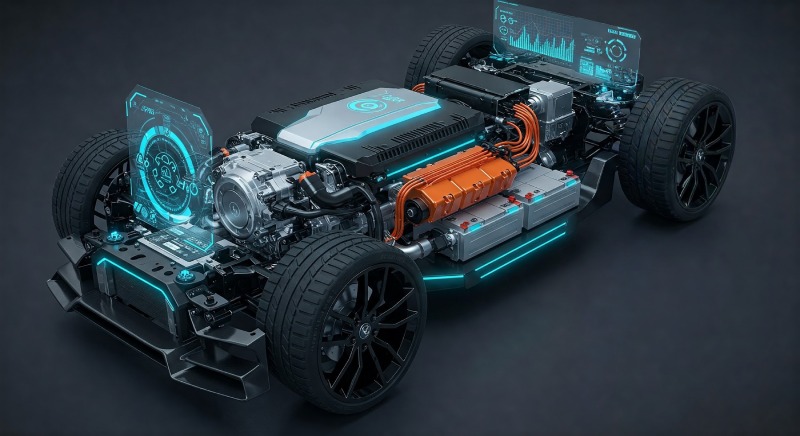

The automotive industry is going on to transform conventional combustion engines into electric ones, but it is not seamlessly doing that. Electric vehicles still face bottlenecks like thermal inefficiencies and power losses, plus applying functional safety. The performance and mass production of electric vehicles are very limited by these factors now. According to one study, warranty claims on electric cars tend to be around 30-50 percent higher than in the case of an internal combustion engine vehicle of similar design. Confronting these challenges is essential to ensure that electric vehicles can meet the requirements of modern transportation while guaranteeing safety and efficiency.

In a globally leading automotive technology company, Raj Rana brings solutions for electrified vehicles to life. They improve power electronic efficiency, reliability, and safety. Raj specializes in high-voltage power conversion systems with a special emphasis on advanced inverter design. The development of high voltage safety standards and powertrain optimization techniques backed by him have contributed towards higher efficiency and functional safety compliance. His work on hardware bring-ups, debugging, and optimization of high-voltage power electronics has set many new benchmarks in power electronics applications.

His outstanding contribution has been to the Hydrogen Fuel Cell Inverter program, where he focused on the design and optimization of the powertrain inverter for improvements in performance, safety, and efficiency. This development allowed the delivery of the first inverter to a customer, a major milestone, which later won a prestigious industry award for excellence in high-voltage power electronics. His multilevel inverter design for EV powertrains further solidified the position of a global leader in automotive technologies as it introduced discrete logic-based safety features that enhanced the reliability of systems and reduced failure scenarios by 40%. Switching losses are reduced, and thermal efficiency is increased. Thus EV powertrains are made more robust and scalable for wide adoption.

Raj hasn’t stopped at these innovations; he encouraged the utilization of functional safety standards and implemented functional safety-relevant circuits for power electronics. In applying his knowledge of PMIC-based safety architecture, active discharge techniques, and hardware security implementation, he has challenged limits to ISO 26262, ensuring that future electrification technologies will be developed to the highest standards of safety and reliability.

His HV discharge techniques achieved significant time reductions in discharge, surpassing industry safety standards. His inverter protection mechanisms also improved, leading to increased EV powertrain reliability. The implementation of discrete safe state logic increased the resilience of systems. This led to decreased malfunctions in high-voltage circuits and an increased lifespan of automotive power electronics.

These impacts have a profound effect beyond their individual product innovations. Raj’s efforts have also enabled better energy efficiency, improvements in system life, and lower operating costs, the critical pieces in breaking the barriers to the widespread adoption of EVs.His accomplishments include developing efficient powertrain solutions and reducing switching losses. These improvements made EV technology scalable and accessible. Furthermore, his contribution to supplier quality assurance and manufacturing optimization has resulted in streamlined production processes geared toward ensuring consistent quality during high-volume production.

The realities of ignoring these challenges would be grave. Without high-voltage safety systems and effective inverter protection strategies, EV manufacturers will incur high defect rates, increase the occurrence of powertrain failures, and initiate safety challenges to compliance – this will lead to a slowed transition to clean energy mobility. Sub-optimality in powertrain cooling systems and loss-reducing strategies will bring energy inefficiencies, diminished vehicle range, and escalated operational costs that would not encourage manufacturers and consumers to invest in electrification-related solutions. The absence of optimized powertrain efficiency will increase the total cost of EV ownership. This will make EVs unviable for mainstream customers and fleet operators to adopt.

Raj’s leadership spans beyond employing technical innovations. It encompasses cross-functional collaborations, mentorship, and research contributions that drive the industry toward sustainable and efficient power conversion systems. With PCB layout, embedded software, mechanical, and supply chain teams, Raj has leveraged functional safety mechanisms and optimized power electronics for long-term reliability, all while ensuring smooth integration. He is an active member of the IEEE Transportation Electrification Council. He participated in conferences such as ECCE and APEC, demonstrating his commitment to innovation in automotive power electronics and educating future engineers. The contribution he has made to technical white papers and industry collaborations has also contributed toward advancing knowledge for powertrain safety, high-voltage control strategies, and inverter optimization techniques.

Also, he has shaped the careers of many aspiring engineers through his passion for knowledge sharing and mentoring. Conducting internal training programs in functional safety and high-voltage design has ensured that new engineers are made aware of the intricate aspects of EV power electronics. His mentoring has helped cross-functional teams work through design challenges. It has also fostered a continuous learning and innovation environment.

Solidifying on his contributions, Raj Rana states, “The future of electrification hinges on reliability, efficiency, and safety. By optimizing high-voltage power systems and integrating advanced safety mechanisms, we are not just improving technology; we are shaping the future of sustainable mobility. Every innovation in power electronics brings us one step closer to making EVs more accessible, efficient, and safe for everyone.”

With the automotive industry making rapid strides toward electrification, power electronics engineers will have an increasingly critical role to play in future mobility based on electric and hydrogen power. Improvements in high-voltage safety, functional reliability, and efficiency of powertrains are vital to overcoming barriers of today in EV technology and then securing future viability. Observed globally, the demand for effective and high-performing power electronics solutions will continue to grow into ever-more institutional commitments to sustainability and zero-emission travel.